Posts

Showing posts from 2011

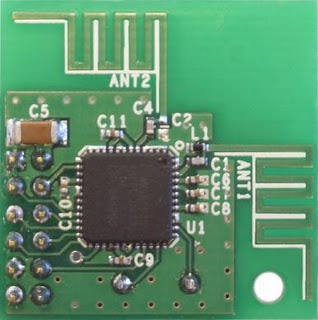

2.4GHz (WiFi) Arduino Spectrum Analyzer - Part 3, CYWM6935 Wireless Radio Module

- Get link

- Other Apps

2.4GHz (WiFi) Arduino Spectrum Analyzer - Part 2, Display

- Get link

- Other Apps

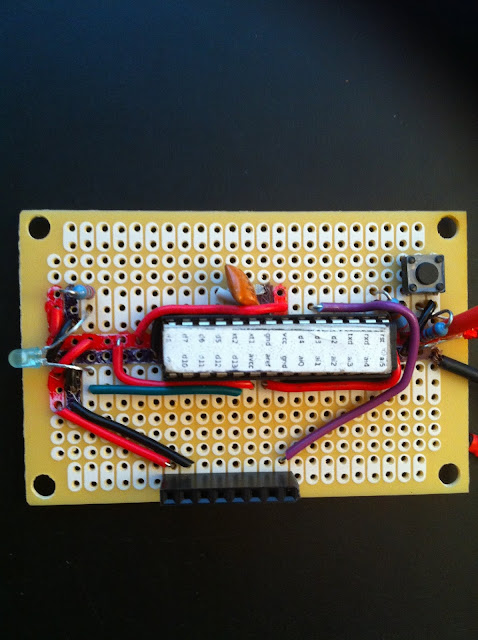

2.4GHz (WiFi) Arduino Spectrum Analyzer - Part 1, Getting Started

- Get link

- Other Apps

2.4GHz Arduino Spectrum Analyzer - Overview

- Get link

- Other Apps

Silverstone SG05 Sandy Bridge Build

- Get link

- Other Apps

Valentine's Heart with Fading/Blinking LEDs

- Get link

- Other Apps

Valentine's Heart with Fading/Blinking LEDs

- Get link

- Other Apps

Adding Arrows and Text in Picasa (Windows)

- Get link

- Other Apps

Changing The iPod Nano 1st Gen Battery

- Get link

- Other Apps

Desoldering? How about drilling those vias out?

- Get link

- Other Apps

AVG and Microsoft Security Essentials

- Get link

- Other Apps

DD-WRT Wireless Slow? Try these out...

- Get link

- Other Apps

Arduino + Power Switch Tail Fountain Controller

- Get link

- Other Apps

Unetbootin: Bootable Lunux on a USB Stick

- Get link

- Other Apps

Python+Arduino = Simple Twitter Search Client

- Get link

- Other Apps

Ubuntu 10.04 Update Flatlined (temporarily) my Ethernet Card

- Get link

- Other Apps